Page 185 - CITS - Fitter Trade Pactical - Volume - 2

P. 185

FITTER - CITS

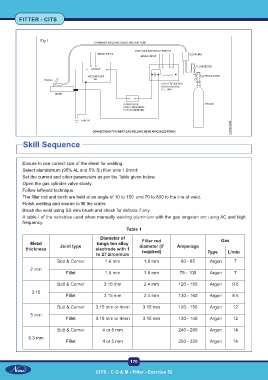

Fig 1

Skill Sequence

Ensure to use correct size of the sheet for welding.

Select aluminimum (95% AL and 5% Si) filler wire 1.6mmf.

Set the current and other parameters as per the Table given below.

Open the gas cylinder valve slowly.

Follow leftward technique.

The filler rod and torch are held at an angle of 10 to 150 and 70 to 800 to the line of weld.

Finish welding and ensure to fill the crater.

Brush the weld using SS wire brush and check for defects if any.

A table-I of the variables used when manually welding aluminium with the gas tungsten arc using AC and high

frequency.

Table 1

Diameter of Gas

Metal tungs ten alloy Filler rod

thickness Joint type electrode with 1 diameter (if Amperage Type L/min

required)

to 27 zirconium

Butt & Corner 1.6 mm 1.6 mm 60 - 85 Argon 7

2 mm

Fillet 1.6 mm 1.6 mm 75 - 100 Argon 7

Butt & Corner 3.15 mm 2.4 mm 120 - 150 Argon 9.5

3.15

Fillet 3.15 mm 2.4 mm 130 - 160 Argon 9.5

Butt & Corner 3.15 mm or 4mm 3.15 mm 120 - 150 Argon 12

5 mm

Fillet 3.15 mm or 4mm 3.15 mm 130 - 160 Argon 12

Butt & Corner 4 or 5 mm 240 - 280 Argon 14

6.3 mm

Fillet 4 or 5 mm 250 - 320 Argon 14

170

CITS : C G & M - Fitter - Exercise 52