Page 210 - CITS - Fitter Trade Pactical - Volume - 2

P. 210

FITTER - CITS

Fig 4

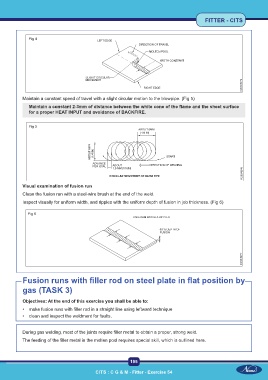

Maintain a constant speed of travel with a slight circular motion to the blowpipe. (Fig 5)

Maintain a constant 2-3mm of distance between the white cone of the flame and the sheet surface

for a proper HEAT INPUT and avoidance of BACKFIRE.

Fig 5

Visual examination of fusion run

Clean the fusion run with a steel-wire brush at the end of the weld.

Inspect visually for uniform width, and ripples with the uniform depth of fusion in job thickness. (Fig 6)

Fig 6

Fusion runs with filler rod on steel plate in flat position by

gas (TASK 3)

Objectives: At the end of this exercise you shall be able to:

• make fusion runs with filler rod in a straight line using leftward technique

• clean and inspect the weldment for faults.

During gas welding, most of the joints require filler metal to obtain a proper, strong weld.

The feeding of the filler metal in the molten pool requires special skill, which is outlined here.

195

CITS : C G & M - Fitter - Exercise 54