Page 215 - CITS - Fitter Trade Pactical - Volume - 2

P. 215

FITTER - CITS

• Set the joint on the welding table in a flat position.

• Deposit root run in the joint by forming a keyhole and obtain complete penetration.

• De-slag and clean the root run and inspect root penetration.

Ensure the crown of penetration is not more than 1.6 mm in height.

• Grind and dress the face of the root run, if required.

• Set the welding current 160 amps for Æ 4mm medium coated M.S. electrode.

• Deposit an intermediate layer i.e. second run over the root run with slight weaving motion using Æ4mm

electrode.

• Clean the intermediate layer thoroughly and inspect for faults. Rectify the defects, if any.

• Deposit the final layer to the weld size using the same current setting, electrode and weaving motion as used

for the second layer.

• Clean the final layer for inspection.

• Inspect the corner fillet weld:

– to ensure uniform and correct reinforcement

– to ensure that the weld face is free from porosity, slag inclusion, unfilled crater, overlap and edge of plate

melted off/insufficient throat thickness.

Skill Sequence

Single ‘Vee’ butt joint in flat position by arc (TASK 1)

Objectives: At the end of this exercise you shall be able to

• single ‘vee’ butt joint in flat position by welding

• prepare the plate edges for single vee butt joint

• set the plates with a root gap of 2mm and proper destortion allowance for single ‘vee’ butt joint

• deposit root bead in termediate and final covering runs in single ‘vee’ butt joint

• clean and inspect the weld for surface defects.

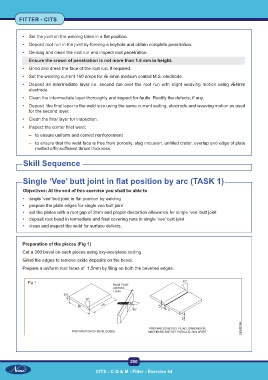

Preparation of the pieces (Fig 1)

Cut a 300 bevel on each pieces using oxy-acetylene cutting.

Grind the edges to remove oxide deposits on the bevel.

Prepare a uniform root faces of 1.5mm by filing on both the bevelled edges.

Fig 1

200

CITS : C G & M - Fitter - Exercise 54