Page 217 - CITS - Fitter Trade Pactical - Volume - 2

P. 217

FITTER - CITS

Fig 4

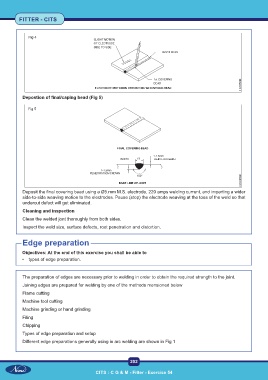

Depostion of final/caping bead (Fig 5)

Fig 5

Deposit the final covering bead using a Ø5.mm M.S. electrode, 220 amps welding current, and imparting a wider

side-to-side weaving motion to the electrodes. Pause (stop) the electrode weaving at the toes of the weld so that

undercut defect will get eliminated.

Cleaning and inspection

Clean the welded jont thoroughly from both sides.

Inspect the weld size, surface defects, root penetration and distortion.

Edge preparation

Objectives: At the end of this exercise you shall be able to

• types of edge preparation.

The preparation of edges are necessary prior to welding in order to obtain the required strength to the joint.

Joining edges are prepared for welding by one of the methods mensioned below

Flame cutting

Machine tool cutting

Machine grinding or hand grinding

Filing

Chipping

Types of edge preparation and setup

Different edge preparations generally using in arc welding are shown in Fig 1

202

CITS : C G & M - Fitter - Exercise 54