Page 102 - CITS - Fitter Trade Practical - Volume -2

P. 102

FITTER - CITS

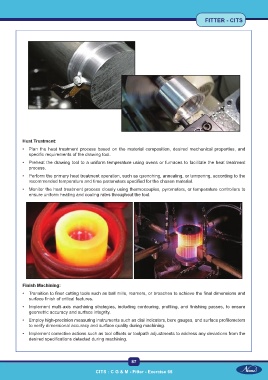

Heat Treatment:

• Plan the heat treatment process based on the material composition, desired mechanical properties, and

specific requirements of the drawing tool.

• Preheat the drawing tool to a uniform temperature using ovens or furnaces to facilitate the heat treatment

process.

• Perform the primary heat treatment operation, such as quenching, annealing, or tempering, according to the

recommended temperature and time parameters specified for the chosen material.

• Monitor the heat treatment process closely using thermocouples, pyrometers, or temperature controllers to

ensure uniform heating and cooling rates throughout the tool.

Finish Machining:

• Transition to finer cutting tools such as ball mills, reamers, or broaches to achieve the final dimensions and

surface finish of critical features.

• Implement multi-axis machining strategies, including contouring, profiling, and finishing passes, to ensure

geometric accuracy and surface integrity.

• Employ high-precision measuring instruments such as dial indicators, bore gauges, and surface profilometers

to verify dimensional accuracy and surface quality during machining.

• Implement corrective actions such as tool offsets or toolpath adjustments to address any deviations from the

desired specifications detected during machining.

87

CITS : C G & M - Fitter - Exercise 68