Page 99 - CITS - Fitter Trade Practical - Volume -2

P. 99

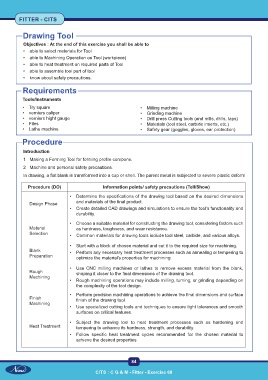

FITTER - CITS

Drawing Tool

Objectives : At the end of this exercise you shall be able to

• able to select materials for Tool

• able to Machining Operation on Tool (workpiece)

• able to heat treatment on required parts of Tool

• able to assemble tool part of tool

• know about safety precautions.

Requirements

Tools/Instruments

• Try square • Milling machine

• verniers caliper • Grinding machine

• verniers hight gauge • Drill press Cutting tools (end mills, drills, taps)

• Files • Materials (tool steel, carbide inserts, etc.)

• Lathe machine • Safety gear (goggles, gloves, ear protection)

Procedure

Introduction

1 Making a Forming Tool for forming profile compone.

2 Machine and personal safety precautions.

In drawing, a flat blank is transformed into a cup or shell. The parent metal is subjected to severe plastic deform

Procedure (DO) Information points/ safety precautions (Tell/Show)

• Determine the specifications of the drawing tool based on the desired dimensions

Design Phase and materials of the final product.

• Create detailed CAD drawings and simulations to ensure the tool’s functionality and

durability.

• Choose a suitable material for constructing the drawing tool, considering factors such

Material as hardness, toughness, and wear resistance.

Selection • Common materials for drawing tools include tool steel, carbide, and various alloys.

• Start with a block of chosen material and cut it to the required size for machining.

Blank • Perform any necessary heat treatment processes such as annealing or tempering to

Preparation optimize the material’s properties for machining.

• Use CNC milling machines or lathes to remove excess material from the blank,

Rough shaping it closer to the final dimensions of the drawing tool.

Machining

• Rough machining operations may include milling, turning, or grinding depending on

the complexity of the tool design.

• Perform precision machining operations to achieve the final dimensions and surface

Finish finish of the drawing tool.

Machining

• Use specialized cutting tools and techniques to ensure tight tolerances and smooth

surfaces on critical features.

• Subject the drawing tool to heat treatment processes such as hardening and

Heat Treatment tempering to enhance its hardness, strength, and durability.

• Follow specific heat treatment cycles recommended for the chosen material to

achieve the desired properties

84

CITS : C G & M - Fitter - Exercise 68