Page 101 - CITS - Fitter Trade Practical - Volume -2

P. 101

FITTER - CITS

• Iterate on the design based on feedback from engineering teams, manufacturing experts, and end-users to

optimize functionality, manufacturability, and cost-effectiveness.

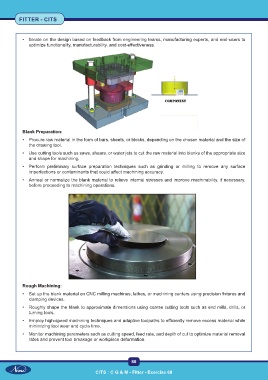

Blank Preparation:

• Procure raw material in the form of bars, sheets, or blocks, depending on the chosen material and the size of

the drawing tool.

• Use cutting tools such as saws, shears, or water jets to cut the raw material into blanks of the appropriate size

and shape for machining.

• Perform preliminary surface preparation techniques such as grinding or milling to remove any surface

imperfections or contaminants that could affect machining accuracy.

• Anneal or normalize the blank material to relieve internal stresses and improve machinability, if necessary,

before proceeding to machining operations.

Rough Machining:

• Set up the blank material on CNC milling machines, lathes, or machining centers using precision fixtures and

clamping devices.

• Roughly shape the blank to approximate dimensions using coarse cutting tools such as end mills, drills, or

turning tools.

• Employ high-speed machining techniques and adaptive toolpaths to efficiently remove excess material while

minimizing tool wear and cycle time.

• Monitor machining parameters such as cutting speed, feed rate, and depth of cut to optimize material removal

rates and prevent tool breakage or workpiece deformation.

86

CITS : C G & M - Fitter - Exercise 68