Page 16 - CITS - Fitter Trade Practical - Volume -2

P. 16

FITTER - CITS

MODULE 6

EXERCISE 58 : Single riveted lap joint

Objectives

At the end of this exercise you shall be able to

• layout the spacing for rivet holes to make single riveted lap joint

• drill the correct size holes using a power operated portable drilling machine

• rivet the snap head rivets with the help of a rivet set, a rivet snap, a dolly using ball peen hammer, to make

single riveted lap joint without a slack.

Job sequence

• Cut and check the given material to the size 140 mm x 48 mm using a steel rule.

• Flatten the sheet on the dressing plate by a mallet.

• Deburr the edges using a flat smooth file.

• Mark the centre line of length 140 mm and cut the sheet into two pieces of size 70 x 48 using straight snips.

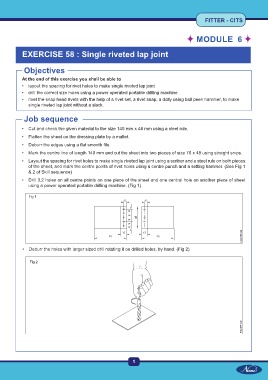

• Layout the spacing for rivet holes to make single riveted lap joint using a scriber and a steel rule on both pieces

of the sheet, and mark the centre points of rivet holes using a centre punch and a setting hammer. (See Fig 1

& 2 of Skill sequence)

• Drill 3.2 holes on all centre points on one piece of the sheet and one central hole on another piece of sheet

using a power operated portable drilling machine. (Fig 1)

Fig 1

• Deburr the holes with larger sized drill rotating it on drilled holes, by hand. (Fig 2)

Fig 2

1