Page 41 - CITS - Fitter Trade Practical - Volume -2

P. 41

FITTER - CITS

Skill Sequence

Drilling through holes

Objectives: At the end of this exercise you shall be able to

• state about drilling through holes.

Punch the centre of the hole to be drilled by a centre punch.

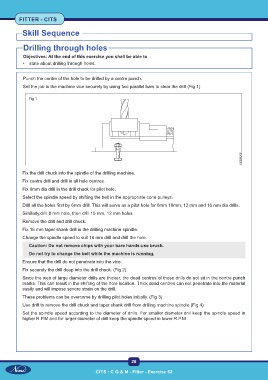

Set the job in the machine vice securely by using two parallel bars to clear the drill (Fig 1)

Fig 1

Fix the drill chuck into the spindle of the drilling machine.

Fix centre drill and drill in all hole centres.

Fix 6mm dia drill in the drill chuck for pilot hole.

Select the spindle speed by shifting the belt in the appropriate cone pulleys.

Drill all the holes first by 6mm drill. This will serve as a pilot hole for 8mm 10mm, 12 mm and 16 mm dia drills.

Similarly,drill 8 mm hole, then drill 10 mm, 12 mm holes.

Remove the drill and drill chuck.

Fix 16 mm taper shank drill in the drilling machine spindle.

Change the spindle speed to suit 16 mm drill and drill the hole.

Caution: Do not remove chips with your bare hands-use brush.

Do not try to change the belt while the machine is running.

Ensure that the drill do not penetrate into the vice.

Fix securely the drill deep into the drill chuck. (Fig 2)

Since the web of large diameter drills are thicker, the dead centres of those drills do not sit in the centre punch

marks. This can result in the shifting of the hole location. Thick dead centres can not penetrate into the material

easily and will impose severe strain on the drill.

These problems can be overcome by drilling pilot holes initially. (Fig 3)

Use drift to remove the drill chuck and taper shank drill from drilling machine spindle (Fig 4)

Set the spindle speed according to the diameter of drills. For smaller diameter drill keep the spindle speed in

higher R.P.M and for larger diameter of drill keep the spindle speed in lower R.P.M.

26

CITS : C G & M - Fitter - Exercise 62