Page 38 - CITS - Fitter Trade Practical - Volume -2

P. 38

FITTER - CITS

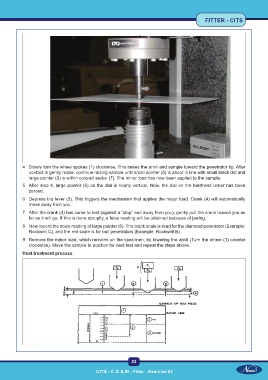

4 Slowly turn the wheel spokes (1) clockwise. This raises the anvil and sample toward the penetrator tip. After

contact is gently made, continue raising sample until small pointer (5) is about in line with small black dot and

large pointer (6) is within colored sector (7). The minor load has now been applied to the sample.

5 After step 4, large pointer (6) on the dial is nearly vertical. Now, the dial on the hardness tester has been

zeroed.

6 Depress trip lever (3). This triggers the mechanism that applies the major load. Crank (4) will automatically

move away from you.

7 After the crank (4) has come to rest (against a “stop” and away from you), gently pull the crank toward you as

far as it will go. If this is done abruptly, a false reading will be obtained because of jarring.

8 Now record the scale reading of large pointer (6). The black scale is read for the diamond penetrator (Example:

Rockwell C), and the red scale is for ball penetrators (Example: Rockwell B).

9 Remove the minor load, which remains on the specimen, by lowering the anvil (Turn the wheel (1) counter

clockwise). Move the sample to position for next test and repeat the steps above.

Heat treatment process

23

CITS : C G & M - Fitter - Exercise 61