Page 46 - CITS - Fitter Trade Practical - Volume -2

P. 46

FITTER - CITS

Check the countersink hole with a suitable countersink head screw for proper seating. (Fig 4)

Fig 4

Counter boring

Objectives: At the end of this exercise you shall be able to

• counterbore holes of different sizes concentric to the drilled holes.

Selection of counterbore sizes

B.I.S. recommends different sizes of counterbores based on the sizes of the clearance holes.

Select the counterbore according to the screw size.

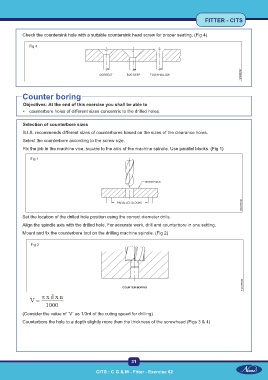

Fix the job in the machine vice, square to the axis of the machine spindle. Use parallel blocks. (Fig 1)

Fig 1

Set the location of the drilled hole position using the correct diameter drills.

Align the spindle axis with the drilled hole. For accurate work, drill and counterbore in one setting.

Mount and fix the counterbore tool on the drilling machine spindle. (Fig 2)

Fig 2

(Consider the value of `V` as 1/3rd of the cuting speed for drilling)

Counterbore the hole to a depth slightly more than the thickness of the screwhead (Figs 3 & 4)

31

CITS : C G & M - Fitter - Exercise 62