Page 49 - CITS - Fitter Trade Practical - Volume -2

P. 49

FITTER - CITS

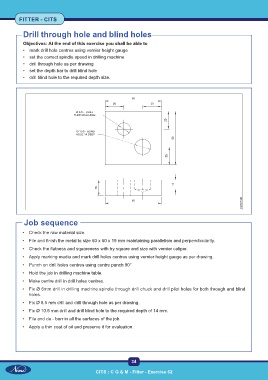

Drill through hole and blind holes

Objectives: At the end of this exercise you shall be able to

• mark drill hole centres using vernier height gauge

• set the correct spindle speed in drilling machine

• drill through hole as per drawing

• set the depth bar to drill blind hole

• drill blind hole to the required depth size.

Job sequence

• Check the raw material size.

• File and finish the metal to size 60 x 60 x 19 mm maintaining parallelism and perpendicularity.

• Check the flatness and squareness with try square and size with vernier caliper.

• Apply marking media and mark drill holes centres using vernier height gauge as per drawing.

• Punch on drill holes centres using centre punch 90°

• Hold the job in drilling machine table.

• Make centre drill in drill holes centres.

• Fix Ø 6mm drill in drilling machine spindle through drill chuck and drill pilot holes for both through and blind

holes.

• Fix Ø 8.5 mm drill and drill through hole as per drawing.

• Fix Ø 10.5 mm drill and drill blind hole to the required depth of 14 mm.

• File and de - burr in all the surfaces of the job.

• Apply a thin coat of oil and preserve it for evaluation.

34

CITS : C G & M - Fitter - Exercise 62