Page 110 - CITS - Fitter - Trade Theory

P. 110

FITTER - CITS

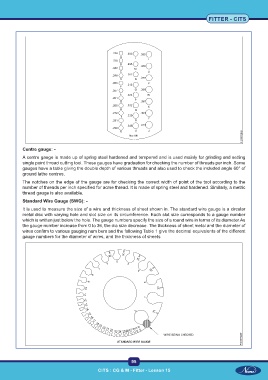

Centre gauge: -

A centre gauge is made up of spring steel hardened and tempered and is used mainly for grinding and setting

single point thread cutting tool. These gauges have graduation for checking the number of threads per inch. Some

gauges have a table giving the double depth of various threads and also used to check the included angle 60° of

ground lathe centres.

The notches on the edge of the gauge are for checking the correct width of point of the tool according to the

number of threads per inch specified for acme thread. It is made of spring steel and hardened. Similarly, a metric

thread gauge is also available.

Standard Wire Gauge (SWG): -

It is used to measure the size of a wire and thickness of sheet shown in. The standard wire gauge is a circular

metal disc with varying hole and slot size on its circumference. Each slot size corresponds to a gauge number

which is written just below the hole. The gauge numbers specify the size of a round wire in terms of its diameter.As

the gauge number increase from 0 to 36, the dia size decrease. The thickness of sheet metal and the diameter of

wires confirm to various gauging num bers and the following Table 1 give the decimal equivalents of the different

gauge numbers for the diameter of wires, and the thickness of sheets

95

CITS : CG & M - Fitter - Lesson 15 CITS : CG & M - Fitter - Lesson 15