Page 145 - CITS - Fitter - Trade Theory

P. 145

FITTER - CITS

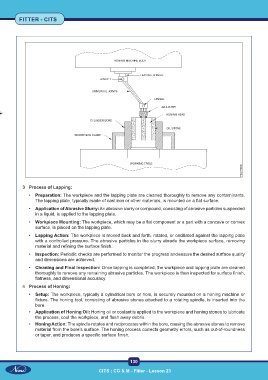

3 Process of Lapping:

• Preparation: The workpiece and the lapping plate are cleaned thoroughly to remove any contaminants.

The lapping plate, typically made of cast iron or other materials, is mounted on a flat surface.

• Application of Abrasive Slurry: An abrasive slurry or compound, consisting of abrasive particles suspended

in a liquid, is applied to the lapping plate.

• Workpiece Mounting: The workpiece, which may be a flat component or a part with a concave or convex

surface, is placed on the lapping plate.

• Lapping Action: The workpiece is moved back and forth, rotated, or oscillated against the lapping plate

with a controlled pressure. The abrasive particles in the slurry abrade the workpiece surface, removing

material and refining the surface finish.

• Inspection: Periodic checks are performed to monitor the progress and ensure the desired surface quality

and dimensions are achieved.

• Cleaning and Final Inspection: Once lapping is completed, the workpiece and lapping plate are cleaned

thoroughly to remove any remaining abrasive particles. The workpiece is then inspected for surface finish,

flatness, and dimensional accuracy.

4 Process of Honing:

• Setup: The workpiece, typically a cylindrical bore or hole, is securely mounted on a honing machine or

fixture. The honing tool, consisting of abrasive stones attached to a rotating spindle, is inserted into the

bore.

• Application of Honing Oil: Honing oil or coolant is applied to the workpiece and honing stones to lubricate

the process, cool the workpiece, and flush away debris.

• Honing Action: The spindle rotates and reciprocates within the bore, causing the abrasive stones to remove

material from the bore’s surface. The honing process corrects geometry errors, such as out-of-roundness

or taper, and produces a specific surface finish.

130

CITS : CG & M - Fitter - Lesson 23