Page 148 - CITS - Fitter - Trade Theory

P. 148

FITTER - CITS

• Improved adhesion for coatings.

• Reduced surface roughness.

• Enhanced biocompatibility.

Uses of Surface Finishing Process

The various uses of the Surface Finishing Process are:

• Enhancing the aesthetic appearance of products.

• Improving corrosion resistance for longevity.

• Enhancing electrical conductivity in electronic components.

• Reducing friction and wear for smoother operation.

• Meeting specific tolerances for precise fits.

• Preparing surfaces for coatings or adhesives.

• Providing stress relief to reduce material fatigue.

• Creating biocompatible surfaces for medical devices.

• Preparing surfaces for bonding in aerospace and automotive applications.

• Restoring antique or worn items to their original condition.

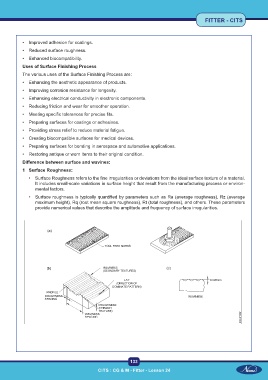

Difference between surface and wavines:

1 Surface Roughness:

• Surface Roughness refers to the fine irregularities or deviations from the ideal surface texture of a material.

It includes small-scale variations in surface height that result from the manufacturing process or environ-

mental factors.

• Surface roughness is typically quantified by parameters such as Ra (average roughness), Rz (average

maximum height), Rq (root mean square roughness), Rt (total roughness), and others. These parameters

provide numerical values that describe the amplitude and frequency of surface irregularities.

133

CITS : CG & M - Fitter - Lesson 24