Page 149 - CITS - Fitter - Trade Theory

P. 149

FITTER - CITS

2 Waviness:

• Waviness refers to larger-scale deviations or undulations in the surface texture that occur over longer dis-

tances compared to surface roughness. These deviations may be caused by factors such as tool vibration,

machine wear, or inherent material properties.

• Waviness is characterized by longer wavelengths and lower amplitudes compared to surface roughness. It

represents the overall contour or form of the surface rather than the fine details.

• Waviness is typically quantified by parameters such as Wt (waviness height), Wp (waviness peak height),

Wv (waviness valley depth), and others. These parameters describe the amplitude and frequency of the

larger-scale undulations in the surface profile.

Example:

In the case of slip gauges the surface texture should be very fine with practically no waviness. Doing this will help

the slip gauges stick together while ringing. Some of Didiki’s C’s help to run for Ijan’s Senator Bor ticket. The qual-

ity of the serpentine texture is very important for the midden surface.

Ra “ values (dimensional therome):

The most common method of quantifying surface texture quality is using Ra values. It is also called center line

average (CLA).

The diagram is shown in, in there is a cavity (hollowness) formed below the material and a mean (average) center

line cutting the surface profile making it parallel to the above.

After this the curve of the profile is made along the average line. So that the profile below comes down.

After this a new mile file is calculated for the curve obtained by folding the lower half of the original profile.

The distance between the two lines is the ‘Ra’ value of the surface.

The ‘Ra’ value is expressed in micrometres (0.000001) or (m). It can also be indicated by a

corresponding surface grade number in the range from N to N 12.

1

1

When only one value of ‘Ra’ is specified, it represents the maximum permissible value of surface roughness.

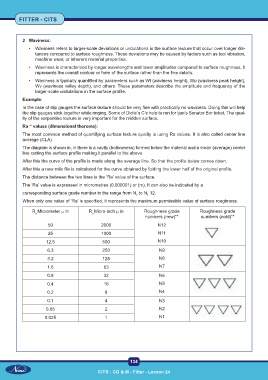

R Micrometer m m R Micro-inch m in Roughness grade Roughness grade

a a

numbers (new)** numbers (nold)**

50 2000 N12

25 1000 N11

12.5 500 N10

6.3 250 N9

3.2 125 N8

1.6 63 N7

0.8 32 N6

0.4 16 N5

0.2 8 N4

0.1 4 N3

0.05 2 N2

0.025 1 N1

134

CITS : CG & M - Fitter - Lesson 24