Page 38 - CITS - Fitter - Trade Theory

P. 38

FITTER - CITS

MODULE 2

LESSON 4 : Types of drilling machine and their specification

Objectives

At the end of this lesson you shall be able to

• identify the various types of drilling machines and its parts and functions

• state the different types of work holding devices

• state the purpose of different types of tool holding devices

• name the different types of drills and its parts, function and uses.

Definition of drilling machine: A drill machine is a tool uses for drilling hole in various material, such as a metal

ceramic wood or plastic.

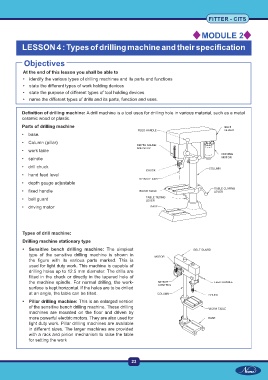

Parts of drilling machine

• base.

• Column (pillar)

• work table

• spindle

• drill chuck

• hand feed level

• depth gauge adjustable

• fixed handle

• belt guard

• driving motor

Types of drill machine:

Drilling machine stationary type

• Sensitive bench drilling machine: The simplest

type of the sensitive drilling machine is shown in

the figure with its various parts marked. This is

used for light duty work. This machine is capable of

drilling holes up to 12.5 mm diameter. The drills are

fitted in the chuck or directly in the tapered hole of

the machine spindle. For normal drilling, the work-

surface is kept horizontal. If the holes are to be drilled

at an angle, the table can be tilted.

• Pillar drilling machine: This is an enlarged version

of the sensitive bench drilling machine. These drilling

machines are mounted on the floor and driven by

more powerful electric motors. They are also used for

light duty work. Pillar drilling machines are available

in different sizes. The larger machines are provided

with a rack and pinion mechanism to raise the table

for setting the work

23

CITS : CG & M - Fitter - Lesson 3