Page 39 - CITS - Fitter - Trade Theory

P. 39

FITTER - CITS

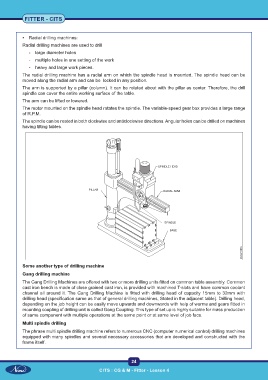

• Radial drilling machines:

Radial drilling machines are used to drill

- large diameter holes

- multiple holes in one setting of the work

- heavy and large work pieces.

The radial drilling machine has a radial arm on which the spindle head is mounted. The spindle head can be

moved along the radial arm and can be locked in any position.

The arm is supported by a pillar (column). It can be rotated about with the pillar as center. Therefore, the drill

spindle can cover the entire working surface of the table.

The arm can be lifted or lowered.

The motor mounted on the spindle head rotates the spindle. The variable-speed gear box provides a large range

of R.P.M.

The spindle can be roated in both clockwise and anticlockwise directions. Angular holes can be drilled on machines

having tilting tables.

Some another type of drilling machine

Gang drilling machine

The Gang Drilling Machines are offered with two or more drilling units fitted on common table assembly. Common

cast iron bench is made of close grained cast iron, is provided with machined T-slots and have common coolant

channel all around it. The Gang Drilling Machine is fitted with drilling head of capacity 15mm to 32mm with

drilling head (specification same as that of general drilling machines, Stated in the adjacent table). Drilling head,

depending on the job height can be easily move upwards and downwards with help of worms and gears fitted in

mounting coupling of drilling unit is called Gang Coupling. This type of set up is highly suitable for mass production

of same component with multiple operations at the same point or at same level of job face.

Multi spindle drilling

The phrase multi spindle drilling machine refers to numerous CNC (computer numerical control) drilling machines

equipped with many spindles and several necessary accessories that are developed and constructed with the

frame itself.

24

CITS : CG & M - Fitter - Lesson 4