Page 88 - CITS - Fitter - Trade Theory

P. 88

FITTER - CITS

3 Applications of Gas Welding:

Gas welding, particularly oxy-acetylene welding (OAW), finds applications across various industries due to its

versatility and capability to weld a wide range of metals. Here are some common applications of gas welding:

• Metal Fabrication and Repair: Gas welding is widely used in metal fabrication shops and repair workshops

for joining and repairing metal components. It is suitable for welding various metals and alloys, including

carbon steel, stainless steel, aluminium, copper, and brass.

• Automotive Repair: Gas welding is commonly used in automotive repair and restoration for tasks such as

panel replacement, frame repair, exhaust system fabrication, and general metal repair work. It allows for

precise control and manipulation of the weld pool, making it suitable for intricate repairs.

• Plumbing and HVAC: Gas welding is utilized in the plumbing and HVAC (Heating, Ventilation, and Air

Conditioning) industries for joining metal pipes, fittings, and components. It is particularly useful for welding

copper pipes in plumbing systems and fabricating HVAC ductwork.

• Metal Sculpture and Artwork: Gas welding is popular among artists and sculptors for creating metal

sculptures, artwork, and decorative pieces. Its versatility allows artists to manipulate metal with precision,

enabling intricate designs and unique forms.

• Shipbuilding and Marine Repair: Gas welding is used in shipbuilding and marine repair industries for joining

and repairing metal structures, hulls, and components of ships, boats, and offshore platforms. It is suitable for

welding marine-grade materials such as stainless steel and aluminium alloys.

• Construction and Structural Fabrication: Gas welding is employed in construction and structural fabrication

for welding metal components, beams, columns, and frameworks used in buildings, bridges, and infrastructure

projects. It provides strong and durable welds for structural applications.

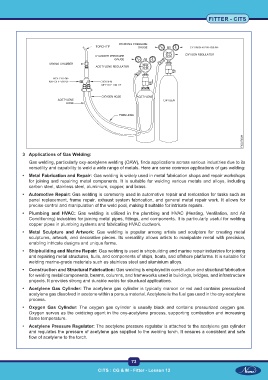

• Acetylene Gas Cylinder: The acetylene gas cylinder is typically maroon or red and contains pressurized

acetylene gas dissolved in acetone within a porous material. Acetylene is the fuel gas used in the oxy-acetylene

process.

• Oxygen Gas Cylinder: The oxygen gas cylinder is usually black and contains pressurized oxygen gas.

Oxygen serves as the oxidizing agent in the oxy-acetylene process, supporting combustion and increasing

flame temperature.

• Acetylene Pressure Regulator: The acetylene pressure regulator is attached to the acetylene gas cylinder

and regulates the pressure of acetylene gas supplied to the welding torch. It ensures a consistent and safe

flow of acetylene to the torch.

73

CITS : CG & M - Fitter - Lesson 12 CITS : CG & M - Fitter - Lesson 12