Page 92 - CITS - Fitter - Trade Theory

P. 92

FITTER - CITS

Simple Edge Preparation: TIG welding typically requires minimal edge preparation, saving time and effort in the

welding preparation process.

Automation is Easy: TIG welding can be easily automated, allowing for increased productivity and consistency

in welding operations.

All-Position Welding: TIG welding can be performed in various positions, including flat, horizontal, vertical, and

overhead, providing flexibility in welding applications.

Produces Desirable Root Penetration in Pipe Welding: TIG welding is favoured for pipe welding due to its

ability to produce desirable root penetration, ensuring strong and reliable weld joints.

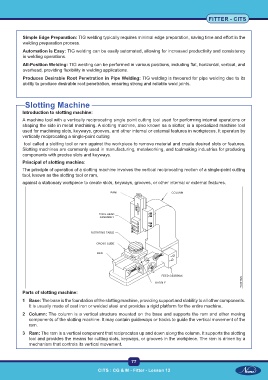

Slotting Machine

Introduction to slotting machine:

A machine tool with a vertically reciprocating single point cutting tool used for performing internal operations or

shaping the side in metal machining. A slotting machine, also known as a slotter, is a specialized machine tool

used for machining slots, keyways, grooves, and other internal or external features in workpieces. It operates by

vertically reciprocating a single-point cutting

tool called a slotting tool or ram against the workpiece to remove material and create desired slots or features.

Slotting machines are commonly used in manufacturing, metalworking, and toolmaking industries for producing

components with precise slots and keyways.

Principal of slotting machine:

The principle of operation of a slotting machine involves the vertical reciprocating motion of a single-point cutting

tool, known as the slotting tool or ram,

against a stationary workpiece to create slots, keyways, grooves, or other internal or external features.

Parts of slotting machine:

1 Base: The base is the foundation of the slotting machine, providing support and stability to all other components.

It is usually made of cast iron or welded steel and provides a rigid platform for the entire machine.

2 Column: The column is a vertical structure mounted on the base and supports the ram and other moving

components of the slotting machine. It may contain guideways or tracks to guide the vertical movement of the

ram.

3 Ram: The ram is a vertical component that reciprocates up and down along the column. It supports the slotting

tool and provides the means for cutting slots, keyways, or grooves in the workpiece. The ram is driven by a

mechanism that controls its vertical movement.

77

CITS : CG & M - Fitter - Lesson 12 CITS : CG & M - Fitter - Lesson 12