Page 97 - CITS - Fitter - Trade Theory

P. 97

FITTER - CITS

MODULE 5

LESSON 13: Introduction To CNC Turning Machine

Objectives

At the end of this lesson you shall be able to

• explain the CNC turning lathe its principles and advantages

• state the classification of CNC system and designation of axis

• state the part programming of CNC turning.

Introduction To Cnc Turning (Lathe) And Advantages

• Introduction of CNC lathe and operations:

CNC (Computer Numerical Control) lathes are advanced machine tools used for precision machining operations

in manufacturing industries. Unlike manual lathes, which require manual operation by skilled machinists, CNC

lathes are automated machines controlled by computer programs to perform various turning operations with high

accuracy and repeatability.

Here’s an introduction to CNC lathes:

1 Basic Principle:

• CNC lathes operate on the principle of rotating a workpiece while a cutting tool removes material from its

surface to create cylindrical or conical shapes.

• The cutting tool is mounted on a tool post and moves along the workpiece’s length to remove material according

to programmed instructions.

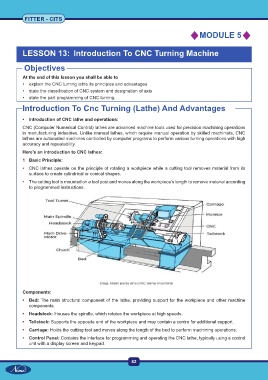

Components:

• Bed: The main structural component of the lathe, providing support for the workpiece and other machine

components.

• Headstock: Houses the spindle, which rotates the workpiece at high speeds.

• Tailstock: Supports the opposite end of the workpiece and may contain a centre for additional support.

• Carriage: Holds the cutting tool and moves along the length of the bed to perform machining operations.

• Control Panel: Contains the interface for programming and operating the CNC lathe, typically using a control

unit with a display screen and keypad.

82