Page 102 - CITS - Fitter - Trade Theory

P. 102

FITTER - CITS

8 Inspect the Finished Part: After machining is complete, inspect the finished part using precision measurement

tools to verify that it meets the specified dimensions and quality requirements.

By following these steps, you can effectively program a CNC lathe to produce precision turned parts according to

your design specification.

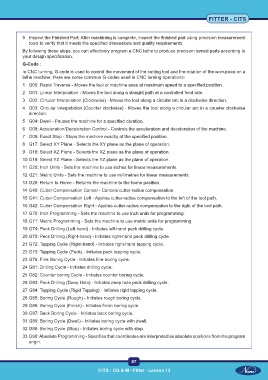

G-Code :

In CNC turning, G-code is used to control the movement of the cutting tool and the rotation of the workpiece on a

lathe machine. Here are some common G-codes used in CNC turning operations:

1 G00: Rapid Traverse - Moves the tool or machine axes at maximum speed to a specified position.

2 G01: Linear Interpolation - Moves the tool along a straight path at a controlled feed rate.

3 G02: Circular Interpolation (Clockwise) - Moves the tool along a circular arc in a clockwise direction.

4 G03: Circular Interpolation (Counter clockwise) - Moves the tool along a circular arc in a counter clockwise

direction.

5 G04: Dwell - Pauses the machine for a specified duration.

6 G08: Acceleration/Deceleration Control - Controls the acceleration and deceleration of the machine.

7 G09: Exact Stop - Stops the machine exactly at the specified position.

8 G17: Select XY Plane - Selects the XY plane as the plane of operation.

9 G18: Select XZ Plane - Selects the XZ plane as the plane of operation.

10 G19: Select YZ Plane - Selects the YZ plane as the plane of operation.

11 G20: Inch Units - Sets the machine to use inches for linear measurements.

12 G21: Metric Units - Sets the machine to use millimetres for linear measurements.

13 G28: Return to Home - Returns the machine to the home position.

14 G40: Cutter Compensation Cancel - Cancels cutter radius compensation.

15 G41: Cutter Compensation Left - Applies cutter radius compensation to the left of the tool path.

16 G42: Cutter Compensation Right - Applies cutter radius compensation to the right of the tool path.

17 G70: Inch Programming - Sets the machine to use inch units for programming.

18 G71: Metric Programming - Sets the machine to use metric units for programming.

19 G74: Peck Drilling (Left-hand) - Initiates left-hand peck drilling cycle.

20 G75: Peck Drilling (Right-hand) - Initiates right-hand peck drilling cycle.

21 G72: Tapping Cycle (Right-hand) - Initiates right-hand tapping cycle.

22 G73: Tapping Cycle (Peck) - Initiates peck tapping cycle.

23 G76: Fine Boring Cycle - Initiates fine boring cycle.

24 G81: Drilling Cycle - Initiates drilling cycle.

25 G82: Counter boring Cycle - Initiates counter boring cycle.

26 G83: Peck Drilling (Deep Hole) - Initiates deep hole peck drilling cycle.

27 G84: Tapping Cycle (Rigid Tapping) - Initiates rigid tapping cycle.

28 G85: Boring Cycle (Rough) - Initiates rough boring cycle.

29 G86: Boring Cycle (Finish) - Initiates finish boring cycle.

30 G87: Back Boring Cycle - Initiates back boring cycle.

31 G89: Boring Cycle (Dwell) - Initiates boring cycle with dwell.

32 G88: Boring Cycle (Stop) - Initiates boring cycle with stop.

33 G90: Absolute Programming - Specifies that coordinates are interpreted as absolute positions from the program

origin.

87

CITS : CG & M - Fitter - Lesson 13 CITS : CG & M - Fitter - Lesson 13