Page 103 - CITS - Fitter - Trade Theory

P. 103

FITTER - CITS

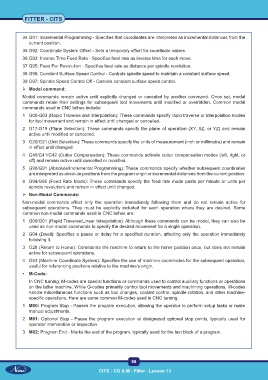

34 G91: Incremental Programming - Specifies that coordinates are interpreted as incremental distances from the

current position.

35 G92: Coordinate System Offset - Sets a temporary offset for coordinate values.

36 G93: Inverse Time Feed Rate - Specifies feed rate as inverse time for each move.

37 G95: Feed Per Revolution - Specifies feed rate as distance per spindle revolution.

38 G96: Constant Surface Speed Control - Controls spindle speed to maintain a constant surface speed.

39 G97: Spindle Speed Control Off - Cancels constant surface speed control.

Modal command:

Modal commands remain active until explicitly changed or canceled by another command. Once set, modal

commands retain their settings for subsequent tool movements until modified or overridden. Common modal

commands used in CNC lathes include:

1 G00-G03 (Rapid Traverse and Interpolation): These commands specify rapid traverse or interpolation modes

for tool movement and remain in effect until changed or cancelled.

2 G17-G19 (Plane Selection): These commands specify the plane of operation (XY, XZ, or YZ) and remain

active until modified or cancelled.

3 G20/G21 (Unit Selection): These commands specify the units of measurement (inch or millimetre) and remain

in effect until changed.

4 G40/G41/G42 (Cutter Compensation): These commands activate cutter compensation modes (left, right, or

off) and remain active until cancelled or modified.

5 G90/G91 (Absolute/Incremental Programming): These commands specify whether subsequent coordinates

are interpreted as absolute positions from the program origin or incremental distances from the current position.

6 G94/G95 (Feed Rate Mode): These commands specify the feed rate mode (units per minute or units per

spindle revolution) and remain in effect until changed.

Non-Modal Commands:

Non-modal commands affect only the operation immediately following them and do not remain active for

subsequent operations. They must be explicitly included for each operation where they are desired. Some

common non-modal commands used in CNC lathes are:

1 G00/G01 (Rapid Traverse/Linear Interpolation): Although these commands can be modal, they can also be

used as non-modal commands to specify the desired movement for a single operation.

2 G04 (Dwell): Specifies a pause or delay for a specified duration, affecting only the operation immediately

following it.

3 G28 (Return to Home): Commands the machine to return to the home position once, but does not remain

active for subsequent operations.

4 G53 (Machine Coordinate System): Specifies the use of machine coordinates for the subsequent operation,

useful for referencing positions relative to the machine’s origin.

• M-Code:

In CNC turning, M-codes are special functions or commands used to control auxiliary functions or operations

on the lathe machine. While G-codes primarily control tool movements and machining operations, M-codes

handle miscellaneous functions such as tool changes, coolant control, spindle rotation, and other machine-

specific operations. Here are some common M-codes used in CNC turning:

1 M00: Program Stop - Pauses the program execution, allowing the operator to perform setup tasks or make

manual adjustments.

2 M01: Optional Stop - Pause the program execution at designated optional stop points, typically used for

operator intervention or inspection.

3 M02: Program End - Marks the end of the program, typically used for the last block of a program.

88

CITS : CG & M - Fitter - Lesson 13