Page 119 - CTS - Mechanic Diesel - TP

P. 119

MECHANIC DIESEL - CITS

5 Clean the nozzle either by blowing air or with a nozzle cleaning Fig 1

wire. Cleaning wire’s (1) diameter should be smaller than spray

hole’s diameter. Ensure that while cleaning wire does not break

inside the hole (Fig 1).

6 Rinse nozzle needle and nozzle with clean testing oil.

7 Hold the nozzle vertically, pull out nozzle needle to 1/3 of its

engaged length and release the nozzle needle. Nozzle needle

should slide down to its seat on its own weight when it is

released.

8 If it does not slide, lap the needle and nozzle body with paste.

9 Clean carbon deposits from inner and outer surfaces of cap nut.

10 Inspect cap nut for any crack/damage.

11 Inspect spring for crack or any damage, replace if necessary.

12 Check spring tension on spring tester. Replace spring if necessary.

13 Dip the body and nozzle in clean oil.

14 Ensure that nozzle and nozzle needle are not interchanged.

15 Hold nozzle body in inverted position on a vice. Place shim, spring, pressure bolt, intermediate washer and

nozzle with needle in nozzle body.

16 Tighten the nozzle cap nut by hand and centralise the nozzle. Then tighten nozzle cap nut at recommended

torque.

TASK 3: Testing of injectors

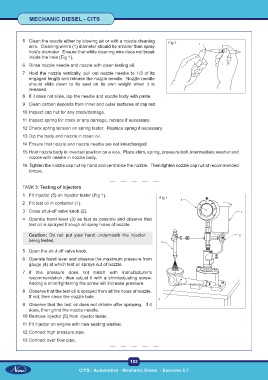

1 Fit injector (5) on injector tester (Fig 1).

Fig 1

2 Fill test oil in container (1).

3 Close shut-off valve knob (2).

4 Operate hand lever (3) as fast as possible and observe that

test oil is sprayed through all spray holes of nozzle.

Caution: Do not put your hand underneath the injector

being tested.

5 Open the shut off valve knob.

6 Operate hand lever and observe the maximum pressure from

gauge (4) at which test oil sprays out of nozzle.

7 If this pressure does not match with manufacturer’s

recommendation, then adjust it with a shim/adjusting screw.

Adding a shim/tightening the screw will increase pressure.

8 Observe that the test oil is sprayed from all the holes of nozzle.

If not, then clean the nozzle hole.

9 Observe that the test oil does not dribble after spraying. If it

does, then grind the nozzle needle.

10 Remove injector (5) from injector tester.

11 Fit injector on engine with new seating washer.

12 Connect high pressure pipe.

13 Connect over flow pipe.

102

CITS : Automotive - Mechanic Diesel - Exercise 5.7