Page 123 - CTS - Mechanic Diesel - TP

P. 123

MECHANIC DIESEL - CITS

TASK 2: Cleaning and Inspection

1 Clean all the parts by kerosene oil.

2 Clean the suction pipe by compressed air.

3 Inspect visually the gears and shafts for pitting and damage.

4 Check visually the contact surface of the oil pump housing and cover for scoring marks.

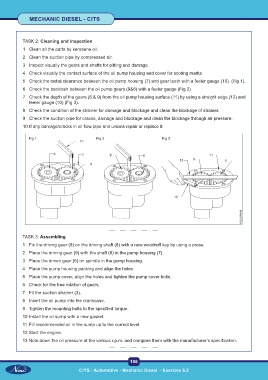

5 Check the radial clearance between the oil pump housing (7) and gear teeth with a feeler gauge (10) (Fig 1).

6 Check the backlash between the oil pump gears (9&6) with a feeler gauge (Fig 2).

7 Check the depth of the gears (6 & 9) from the oil pump housing surface (11) by using a straight edge (12) and

feeler gauge (10) (Fig 3).

8 Check the condition of the strainer for damage and blockage and clean the blockage of strainer.

9 Check the suction pipe for cracks, damage and blockage and clean the blockage through air pressure.

10 If any damage/cracks in oil flow pipe and unions repair or replace it.

Fig 1 Fig 2 Fig 3

TASK 3: Assembling

1 Fix the driving gear (9) on the driving shaft (8) with a new woodruff key by using a press.

2 Place the driving gear (9) with the shaft (8) in the pump housing (7).

3 Place the driven gear (6) on spindle in the pump housing.

4 Place the pump housing packing and align the holes.

5 Place the pump cover, align the holes and tighten the pump cover bolts.

6 Check for the free rotation of gears.

7 Fit the suction strainer (3).

8 Insert the oil pump into the crankcase.

9 Tighten the mounting bolts to the specified torque.

10 Install the oil sump with a new gasket.

11 Fill recommended oil in the sump up to the correct level.

12 Start the engine.

13 Note down the oil pressure at the various r.p.m. and compare them with the manufacturer’s specification.

106

CITS : Automotive - Mechanic Diesel - Exercise 6.2