Page 216 - CTS - Mechanic Diesel - TP

P. 216

MECHANIC DIESEL - CITS

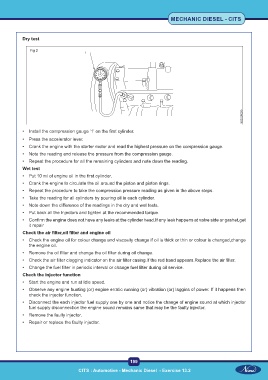

Dry test

Fig 2

• Install the compression gauge ‘1’ on the first cylinder.

• Press the accelerator lever.

• Crank the engine with the starter motor and read the highest pressure on the compression gauge.

• Note the reading and release the pressure from the compression gauge.

• Repeat the procedure for all the remaining cylinders and note down the reading.

Wet test

• Put 10 ml of engine oil in the first cylinder.

• Crank the engine to circulate the oil around the piston and piston rings.

• Repeat the procedure to take the compression pressure reading as given in the above steps.

• Take the reading for all cylinders by pouring oil in each cylinder.

• Note down the difference of the readings in the dry and wet tests.

• Put back all the Injectors and tighten at the recommended torque.

• Confirm the engine does not have any leaks at the cylinder head.If any leak happens at valve side or gashet,get

it repair

Check the air filter,oil filter and engine oil

• Check the engine oil for colour change and viscosity change if oil is thick or thin or colour is changed,change

the engine oil.

• Remove the oil filter and change the oil filter during oil change.

• Check the air filter clogging indicator on the air filter casing.If the red band appears.Replace the air filter.

• Change the fuel filter in periodic interval or change fuel filter during oil service.

Check the injector function

• Start the engine and run at Idle speed.

• Observe any engine hunting (or) engine erratic running (or) vibration (or) laggins of power. If it happens then

check the injector function.

• Disconnect the each injector fuel supply one by one and notice the change of engine sound at which injector

fuel supply disconnection the engine sound remains same that may be the faulty injector.

• Remove the faulty injector.

• Repair or replace the faulty injector.

199

CITS : Automotive - Mechanic Diesel - Exercise 13.2