Page 276 - CTS - Mechanic Diesel - TP

P. 276

MECHANIC DIESEL - CITS

Fix the end play measuring attachment with dial gauge to cam- shaft (drive end). During this measurement,

the roller tappets should be lifted off the camshaft with suitable tappet lifters. Exert a steady axial pull on the

attachment (Fig 7) and set dial indicator to ‘0’. Then exert a steady axial pressure on the attachment and note

down the reading.

The camshaft end play showing in the Tabular Colum:

Ball bearings Taper roller bearings Corresponding ambient

temperature

0.03 to 0.13 mm 0.02 to 0.06 mm Around 20° C

0.07 to 0.17 mm 0.06 to 0.10 mm Around 40° C

If ‘excessive end play or no play’ exists, the camshaft should be removed. At this stage it is advisable to remove

shims totalling at least 0.2 mm thickness as it is easier to measure accurately when some play exists. Refit

camshaft (avoid using grease since it influences the measurement). Measure end play and if required add shims

between spacer ring and bearing.

Keep thrust lever and spring inside the governor housing and insert lever shaft

Secure thrust lever on lever shaft with screw .

Hook the spring to thrust lever. Add equal number of shims , washer on both sides and assemble split pins .

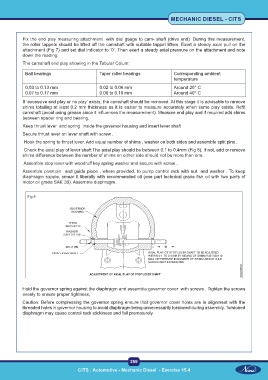

Check the axial play of lever shaft The axial play should be between 0.1 to 0.4mm (Fig 8). If not, add or remove

shims difference between the number of shims on either side should not be more than one.

Assemble stop lever with woodruff key spring washer and secure with screw .

Assemble pivot pin and guide piece , where provided, to pump control rack with nut and washer . To keep

diaphragm supple, smear it liberally with recommended oil (one part technical grade fish oil with two parts of

motor oil grade SAE 30). Assemble diaphragm.

Fig 8

Hold the governor spring against the diaphragm and assemble governor cover with screws . Tighten the screws

evenly to ensure proper tightness,

Caution: Before compressing the governor spring ensure that governor cover holes are in alignment with the

threaded holes in governor housing to avoid diaphragm being unnecessarily torsioned during assembly. Torsioned

diaphragm may cause control rack stickiness and fail prematurely.

259

CITS : Automotive - Mechanic Diesel - Exercise 15.4