Page 277 - CTS - Mechanic Diesel - TP

P. 277

MECHANIC DIESEL - CITS

Assembly of end cover

Smear mutton tallow on ‘0’ rings and assemble ‘0’ rings into the corresponding counterbores of end cover

Assemble equal number of washers .

Assemble washer and split pin on the opposite side of control lever. Assemble bush , spring . The spring should

be assembled such that the straight end (parallel to spring axis) is engaged in the corresponding groove on end

cover and U bent end is hooked on to control lever.

Engage the tenons of lever shaft to the corresponding hole of control lever and fix screw along with spring

washer . In the case of new design where hexagonal head screw is provided, assemble plain washer, spring

washer and fix the screw .

Tighten the screw (to 6 N.m (0.6 kgf. m) torque.

Check the axial play of lever shaft. The axial play should be between 0.1 and 0.4 mm (Fig 9). If not, add or remove

washer . The difference between the number of washers on either side should not be more than one. Check for

free movement of lever shaft. Smear good quality grease on the cam and the lever shaft near the bearing bushes.

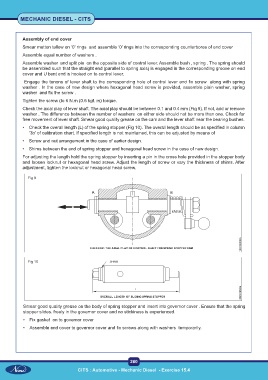

• Check the overall length (L) of the spring stopper (Fig 10). The overall length should be as specified in column

‘3b’ of calibration chart. If specified length is not maintained, this can be adjusted by means of

• Screw and nut arrangement in the case of earlier design.

• Shims between the end of spring stopper and hexagonal head screw in the case of new design.

For adjusting the length hold the spring stopper by inserting a pin in the cross hole provided in the stopper body

and loosen locknut or hexagonal head screw. Adjust the length of screw or vary the thickness of shims. After

adjustment, tighten the locknut or hexagonal head screw.

Fig 9

Fig 10

Smear good quality grease on the body of spring stopper and insert into governor cover . Ensure that the spring

stopper slides. freely in the governor cover and no stickiness is experienced.

• Fix gasket on to governor cover

• Assemble end cover to governor cover and fix screws along with washers temporarily.

260

CITS : Automotive - Mechanic Diesel - Exercise 15.4