Page 46 - CTS - Mechanic Diesel - TP

P. 46

MECHANIC DIESEL - CITS

EXERCISE 2.10: Practice on removing the valves from the

cylinder head

Objectives

At the end of this exercise you shall be able to

• remove the valves and its parts from cylinder head and clean the parts.

Requirements

Tools/Instruments

• Trainee’s tool kit - 1 No. • Dial gauge with stand - 1 No.

• Valve spring lifter - 1 No.

• Wire brush, scrapper - 1 No each. Materials/Components

Equipments/Machines • Tray - 1 No

• Cotton cloth - as reqd.

• Multi cylinder diesel engine - 1 No. • Kerosene - as reqd.

• V block - Set. • Lube oil - as reqd.

• Spring tester - 1 No.

Procedure v

Remove valves

• Place the cylinder head on a work bench over the two wooden block stands.

• Mark the valves

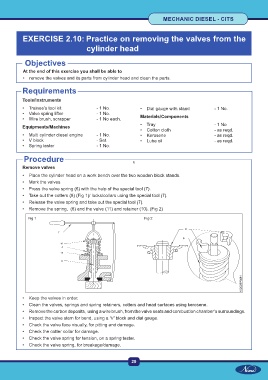

• Press the valve spring (6) with the help of the special tool (7).

• Take out the cotters (8) (Fig 1)/ locks/collars using the special tool (7).

• Release the valve spring and take out the special tool (7).

• Remove the spring, (6) and the valve (11) and retainer (10). (Fig 2)

Fig 1 Fig 2

• Keep the valves in order.

• Clean the valves, springs and spring retainers, cotters and head surfaces using kerosene.

• Remove the carbon deposits, using a wire brush, from the valve seats and combustion chamber’s surroundings.

• Inspect the valve stem for bend, using a ‘V’ block and dial gauge.

• Check the valve face visually, for pitting and damage.

• Check the cotter collar for damage.

• Check the valve spring for tension, on a spring tester.

• Check the valve spring, for breakage/damage.

29