Page 50 - CTS - Mechanic Diesel - TP

P. 50

MECHANIC DIESEL - CITS

EXERCISE 2.13: Assembling the cylinder head

Objectives

At the end of this exercise you shall be able to

• check the spring tension on a spring tester

• check tappets, pushrods, tappets screws and valve stem

• refit the cylinder head and manifolds.

Requirements

Tools/Instruments Materials/Components

• Trainee’s tool kit - 1 No. • Cotton cloth - 1 No.

• Valve spring compressor - 1 No. • Engine oil - as reqd.

• Feeler gauge - 1 No. • Head gasket - as reqd.

• Valve springs - as reqd.

Equipments/Machines

• Head stud nuts - as reqd.

• Spring tester - 1 No.

• Torque wrench - 1 No.

• Oil can - 1 No.

Procedure

• Clean the spring to be tested.

• Clean the spring tester.

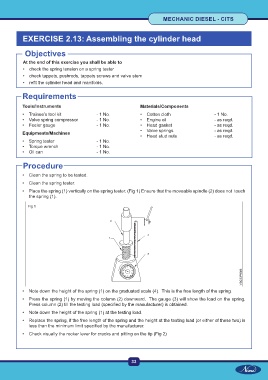

• Place the spring (1) vertically on the spring tester. (Fig 1) Ensure that the moveable spindle (2) does not touch

the spring (1).

Fig 1

• Note down the height of the spring (1) on the graduated scale (4). This is the free length of the spring.

• Press the spring (1) by moving the column (2) downward. The gauge (3) will show the load on the spring.

Press column (2) till the testing load (specified by the manufacturer) is obtained.

• Note down the height of the spring (1) at the testing load.

• Replace the spring, if the free length of the spring and the height at the testing load (or either of these two) is

less than the minimum limit specified by the manufacturer.

• Check visually the rocker lever for cracks and pitting on the tip (Fig 2)

33