Page 74 - CTS - Mechanic Diesel - TP

P. 74

MECHANIC DIESEL - CITS

• Note down the thickness of the thickest leaf, which can be inserted between the straight edge and the surface

of the cylinder block. This thickness gives the maximum face out in the direction.

• Repeat the above steps in different direction and places on the surface of cylinder block and note down the

maximum face out in all directions.

• Recommend for replacing or resurfacing of cylinder block if maximum face out is more than the specified limit

by the manufacturers.

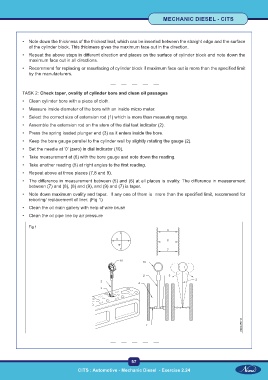

TASK 2: Check taper, ovality of cylinder bore and clean oil passages

• Clean cylinder bore with a piece of cloth.

• Measure inside diameter of the bore with an inside micro meter.

• Select the correct size of extension rod (1) which is more than measuring range.

• Assemble the extension rod on the stem of the dial test indicator (2).

• Press the spring loaded plunger end (3) as it enters inside the bore.

• Keep the bore gauge parallel to the cylinder wall by slightly rotating the gauge (2).

• Set the needle at ‘0’ (zero) in dial indicator (10).

• Take measurement at (6) with the bore gauge and note down the reading.

• Take another reading (5) at right angles to the first reading.

• Repeat above at three places (7,8 and 9).

• The difference in measurement between (5) and (6) at all places is ovality. The difference in measurement

between (7) and (8), (8) and (9), and (9) and (7) is taper.

• Note down maximum ovality and taper. If any one of them is more than the specified limit, recommend for

reboring/ replacement of liner. (Fig 1)

• Clean the oil main gallery with help of wire brush

• Clean the oil pipe line by air pressure

Fig 1

57

CITS : Automotive - Mechanic Diesel - Exercise 2.24