Page 76 - CTS - Mechanic Diesel - TP

P. 76

MECHANIC DIESEL - CITS

• Place the main bearing shell into its respective parent bore. Ensure that the oil holes of the bearing shell and

that of the parent bore are perfectly aligned.

• Install the crank shaft rear bearing seal (oil seal). Insert the rubber packing (rubber rod) in the holes between

the bearing cap and the cylinder block.

• The projection of the rubber packing should not be more than 6 mm. If it is more than 6 mm, cut off the excess

length.

• Install the thrust washers into the respective bearings.

• Lubricate all the bearing surfaces with clean engine oil.

• Place the crank shaft in its position in the cylinder block.

• Place the shell bearings into their respective bearing caps.

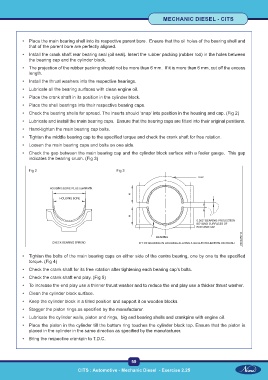

• Check the bearing shells for spread. The inserts should ‘snap’ into position in the housing and cap. (Fig 2)

• Lubricate and install the main bearing caps. Ensure that the bearing caps are fitted into their original positions.

• Hand-tighten the main bearing cap bolts.

• Tighten the middle bearing cap to the specified torque and check the crank shaft for free rotation.

• Loosen the main bearing caps and bolts on one side.

• Check the gap between the main bearing cap and the cylinder block surface with a feeler gauge. This gap

indicates the bearing crush. (Fig 3)

Fig 2 Fig 3

• Tighten the bolts of the main bearing caps on either side of the centre bearing, one by one to the specified

torque. (Fig 4)

• Check the crank shaft for its free rotation after tightening each bearing cap’s bolts.

• Check the crank shaft end play. (Fig 5)

• To increase the end play use a thinner thrust washer and to reduce the end play use a thicker thrust washer.

• Clean the cylinder block surface.

• Keep the cylinder block in a tilted position and support it on wooden blocks.

• Stagger the piston rings as specified by the manufacturer.

• Lubricate the cylinder walls, piston and rings, big end bearing shells and crankpins with engine oil.

• Place the piston in the cylinder till the bottom ring touches the cylinder block top. Ensure that the piston is

placed in the cylinder in the same direction as specified by the manufacturer.

• Bring the respective crankpin to T.D.C.

59

CITS : Automotive - Mechanic Diesel - Exercise 2.25