Page 117 - Mechanic Diesel - TT

P. 117

MECHANIC DIESEL - CITS

In some fuel pumps hand priming lever are fitted with fuel line and carburetor is filled with petrol before starting

the engine.

If such lever is out fitted then engine which is not used for long time or engine which is overhaul and carburetor

open, to starts these first should be filled up the float bowl with petrol after opening the top cover of carburetor.

In mechanical pumps parts are normally damage after sometimes like returning spring and diaphragm crack, due

to these condition sometimes valve is not work properly therefore it should check time to time. If they should need

replaced, then replaced it.

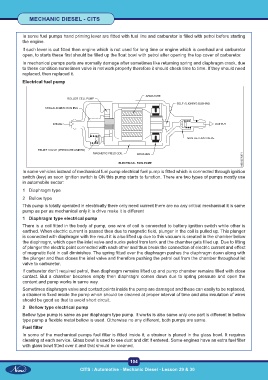

Electrical fuel pump

In some vehicles instead of mechanical fuel pump electrical fuel pump is fitted which is connected through ignition

switch (key) as soon ignition switch is ON this pump starts to function. There are two types of pumps mostly use

in automobile sector:

1 Diaphragm type

2 Bellow type

This pump is totally operated in electrically there only need current there are no any critical mechanical it is same

pump as per as mechanical only it is drive make it is different

1 Diaphragm type electrical pump

There is a coil fitted in the body of pump, one wire of coil is connected to battery ignition switch while other is

earthed. When electric current is passed then due to magnetic field, plunger in the coil is pulled up. This plunger

is connected with diaphragm with the result it is also lifted up due to this vacuum is created in the chamber below

the diaphragm, which open the inlet valve and sucks petrol from tank and the chamber gets filled up. Due to lifting

of plunger the electric point connected with each other and thus break the connection of electric current and effect

of magnetic field in coil diminishes. The spring fitted over the diaphragm pushes the diaphragm down along with

the plunger and thus closes the inlet valve and therefore pushing the petrol out from the chamber throughout let

valve to carburetor.

If carburetor don’t required petrol, then diaphragm remains lifted up and pump chamber remains filled with close

contact. But a chamber becomes empty then diaphragm comes down due to spring pressure and open the

content and pump works in same way.

Sometimes diaphragm valve and contact points inside the pump are damaged and these can easily to be replaced,

a strainer is fixed inside the pump which should be cleaned at proper interval of time and also insulation of wires

should be good so that to avoid short circuit.

2 Bellow type electrical pump

Bellow type pump is same as per diaphragm type pump. It works is also same only one part is different in bellow

type pump a flexible metal bellow is used. Otherwise no any different, both pumps are same.

Fuel filter

In some of the mechanical pumps fuel filter is fitted inside it, a strainer is placed in the glass bowl. It requires

cleaning at each service. Glass bowl is used to see dust and dirt if entered. Some engines have an extra fuel filter

with glass bowl fitted over it and that should be cleaned.

104

CITS : Automotive - Mechanic Diesel - Lesson 29 & 30