Page 121 - Mechanic Diesel - TT

P. 121

MECHANIC DIESEL - CITS

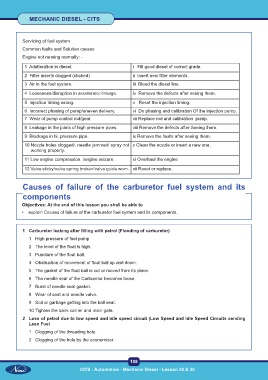

Servicing of fuel system

Common faults and Solution causes

Engine not running normally: -

1 Adulteration in diesel. i Fill good diesel of correct grade.

2 Filter inserts clogged (choked) ii Insert new filter elements.

3 Air in the fuel system. iii Bleed the diesel line

4 Looseness/disruption in accelerator linkage. iv Remove the defects after seeing them.

5 Injection timing wrong. v Reset the injection timing.

6 Incorrect phasing of pump/uneven delivery. vi Do phasing and calibration Of the injection pump.

7 Wear of pump control rod/gear. vii Replace rod and calibration pump.

8 Leakage in the joints of high pressure pipes. viii Remove the defects after Seeing them.

9 Blockage in hi. pressure pipe. ix Remove the faults after seeing them.

10 Nozzle holes clogged/. needle jammed/ spray not x Clean the nozzle or insert a new one.

working properly.

11 Low engine compression. /engine seizure. xi Overhaul the engine

12 Valve sticky/valve spring broken/valve guide worn. xii Reset or replace.

Causes of failure of the carburetor fuel system and its

components

Objectives: At the end of this lesson you shall be able to

• explain Causes of failure of the carburetor fuel system and its components.

1 Carburetor leaking after filling with petrol (Flooding of carburetor)

1 High pressure of fuel pump

2 The level of the float is high.

3 Puncture of the float ball.

4 Obstruction of movement of float ball up and down.

5 The gasket of the float ball is cut or moved from its place.

6 The needle seat of the Carburetor becomes loose.

7 Burst of needle seat gasket.

8 Wear of seat and needle valve.

9 Soil or garbage getting into the ball seat.

10 Tighten the bank carrier and main gate.

2 Loss of petrol due to low speed and idle speed circuit (Low Speed and Idle Speed Circuits sending

Lean Fuel

1 Clogging of the threading hole.

2 Clogging of the hole by the economizer.

108

CITS : Automotive - Mechanic Diesel - Lesson 29 & 30