Page 158 - Mechanic Diesel - TT

P. 158

MECHANIC DIESEL - CITS

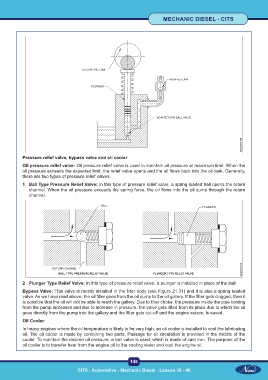

Pressure relief valve, bypass valve and oil cooler

Oil pressure relief valve: Oil pressure relief valve is used to maintain oil pressure at maximum limit. When the

oil pressure exceeds the expected limit, the relief valve opens and the oil flows back into the oil tank. Generally,

there are two types of pressure relief valves.

1 Ball Type Pressure Relief Valve: In this type of pressure relief valve, a spring loaded ball opens the return

channel. When the oil pressure exceeds the spring force, the oil flows into the oil sump through the return

channel.

2 Plunger Type Relief Valve: In this type of pressure relief valve, a plunger is installed in place of the ball.

Bypass Valve: This valve is mostly installed in the filter body (see Figure 21.31) and it is also a spring loaded

valve. As we have read above, the oil filter goes from the oil pump to the oil gallery. If the filter gets clogged, then it

is possible that the oil will not be able to reach the gallery. Due to filter choke, the pressure inside the pipe coming

from the pump increases and due to increase in pressure, the valve gets lifted from its place due to which the oil

goes directly from the pump into the gallery and the filter gets cut-off and the engine seizes. Is saved.

Oil Cooler:

In heavy engines where the oil temperature is likely to be very high, an oil cooler is installed to cool the lubricating

oil. The oil cooler is made by combining two parts. Passage for oil circulation is provided in the middle of the

cooler. To maintain the desired oil pressure, a ball valve is used, which is made of cast iron. The purpose of the

oil cooler is to transfer heat from the engine oil to the cooling water and cool the engine oil.

145

CITS : Automotive - Mechanic Diesel - Lesson 39 - 46 CITS : Automotive - Mechanic Diesel - Lesson 39 - 46