Page 185 - Mechanic Diesel - TT

P. 185

MECHANIC DIESEL - CITS

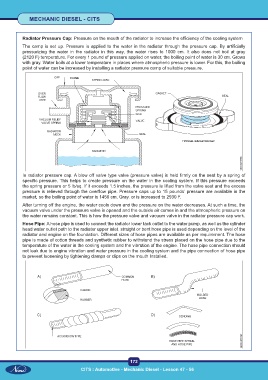

Radiator Pressure Cap: Pressure on the mouth of the radiator to increase the efficiency of the cooling system

The camp is set up. Pressure is applied to the water in the radiator through the pressure cap. By artificially

pressurizing the water in the radiator in this way, the water rises to 1000 cm. It also does not boil at gray

(2120 F) temperature. For every 1 pound of pressure applied on water, the boiling point of water is 30 cm. Grows

with gray. Water boils at a lower temperature in places where atmospheric pressure is lower. For this, the boiling

point of water can be increased by installing a radiator pressure camp of suitable pressure.

In radiator pressure cap. A blow off valve type valve (pressure valve) is held firmly on the seat by a spring of

specific pressure. This helps to create pressure on the water in the cooling system. If this pressure exceeds

the spring pressure or 5 lb/sq. If it exceeds 1.5 inches, the pressure is lifted from the valve seat and the excess

pressure is relieved through the overflow pipe. Pressure caps up to 15 pounds’ pressure are available in the

market, so the boiling point of water is 1450 cm. Gray. or is increased to 2930 F.

After turning off the engine, the water cools down and the pressure on the water decreases. At such a time, the

vacuum valve under the pressure valve is opened and the outside air comes in and the atmospheric pressure on

the water remains constant. This is how the pressure valve and vacuum valve in the radiator pressure cap work.

Hose Pipe: A hose pipe is used to connect the radiator lower tack outlet to the water pump, as well as the cylinder

head water outlet path to the radiator upper inlet. straight or bent hose pipe is used depending on the level of the

radiator and engine on the foundation. Different sizes of hose pipes are available as per requirement. The hose

pipe is made of cotton threads and synthetic rubber to withstand the stress placed on the hose pipe due to the

temperature of the water in the cooling system and the vibration of the engine. The hose pipe connection should

not leak due to engine vibration and water pressure in the cooling system and the pipe connection of hose pipe

to prevent loosening by tightening clamps or clips on the mouth Installed.

172

CITS : Automotive - Mechanic Diesel - Lesson 47 - 56