Page 187 - Mechanic Diesel - TT

P. 187

MECHANIC DIESEL - CITS

Booster Pumps: These pumps are used to increase the pressure of water in a system. They are often used in

buildings or homes where the water pressure from the main supply is not sufficient.

Sump Pumps: Sump pumps are used to remove water that has accumulated in a sump pit, typically found in

basements. They are designed to pump water away from the building to prevent flooding.

Mechanical Water Pump: This type of water pump is driven by a belt connected to the engine’s crankshaft. It

circulates coolant through the engine and radiator to maintain optimal operating temperature.

In a mechanical water pump

Centrifugal Pump: This is the most common type of water pump used in automobiles. It uses a rotating impeller

to create a centrifugal force that pushes the coolant outward, increasing its pressure and flow rate.

Axial Flow Pump: This type of pump uses propeller-like blades to move coolant parallel to the pump shaft. It’s

often used in applications where a high flow rate is required.

Mixed Flow Pump: A mixed flow pump combo of the features of centrifugal and axial flow pumps. It uses a

combination of radial and axial flow to move coolant, providing a balance between flow rate and pressure.

Diaphragm Pump: This type of pump uses a diaphragm to create suction and push coolant through the system.

It’s often used in applications where a smooth and pulse-free flow is required.

Study about electric fan, thermostat, fan belts, temperature gauge, temperature sensor

Electric fan

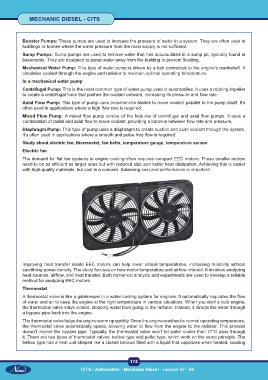

The demand for flat fan systems in engine cooling often requires compact EEC motors. These smaller motors

need to be as efficient as larger ones but with reduced size and better heat dissipation. Achieving this is easier

with high-quality materials, but cost is a concern. Balancing cost and performance is important.

Improving heat transfer inside EEC motors can help lower critical temperatures, increasing reliability without

sacrificing power density. The study focuses on how motor temperature and airflow interact. It involves analyzing

heat sources, airflow, and heat transfer. Both numerical analysis and experiments are used to develop a reliable

method for analyzing EEC motors.

Thermostat

A thermostat valve is like a gatekeeper in a water cooling system for engines. It automatically regulates the flow

of water and air to keep the engine at the right temperature in various situations. When you start a cold engine,

the thermostat valve stays closed, stopping water from going to the radiator. Instead, it directs the water through

a bypass pipe back into the engine.

The thermostat valve helps the engine warm up quickly. Once the engine reaches its normal operating temperature,

the thermostat valve automatically opens, allowing water to flow from the engine to the radiator. This process

doesn’t involve the bypass pipe. Typically, the thermostat valve won’t let water cooler than 77°C pass through

it. There are two types of thermostat valves: bellow type and pellet type, which work on the same principle. The

bellow type has a heat unit shaped like a closed bellows filled with a liquid that vaporizes when heated, causing

174

CITS : Automotive - Mechanic Diesel - Lesson 47 - 56