Page 182 - Mechanic Diesel - TT

P. 182

MECHANIC DIESEL - CITS

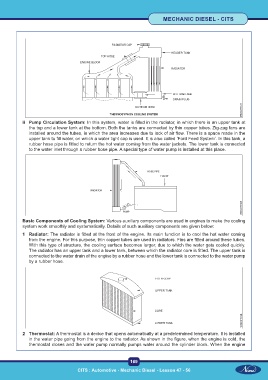

ii Pump Circulation System: In this system, water is filled in the radiator, in which there is an upper tank at

the top and a lower tank at the bottom. Both the tanks are connected by thin copper tubes. Zig-zag fans are

installed around the tubes, in which the area increases due to lack of air flow. There is a space made in the

upper tank to fill water, on which a water tight cap is used. It is also called ‘Ford Feed System’. In this tank, a

rubber hose pipe is fitted to return the hot water coming from the water jackets. The lower tank is connected

to the water inlet through a rubber hose pipe. A special type of water pump is installed at this place.

Basic Components of Cooling System: Various auxiliary components are used in engines to make the cooling

system work smoothly and systematically. Details of such auxiliary components are given below:

1 Radiator: The radiator is fitted at the front of the engine. Its main function is to cool the hot water coming

from the engine. For this purpose, thin copper tubes are used in radiators. Fins are fitted around these tubes.

With this type of structure, the cooling surface becomes larger, due to which the water gets cooled quickly.

The radiator has an upper tank and a lower tank, between which the radiator core is fitted. The upper tank is

connected to the water drain of the engine by a rubber hose and the lower tank is connected to the water pump

by a rubber hose.

2 Thermostat: A thermostat is a device that opens automatically at a predetermined temperature. It is installed

in the water pipe going from the engine to the radiator. As shown in the figure, when the engine is cold, the

thermostat closes and the water pump normally pumps water around the cylinder block. When the engine

169

CITS : Automotive - Mechanic Diesel - Lesson 47 - 56 CITS : Automotive - Mechanic Diesel - Lesson 47 - 56