Page 225 - CTS - Sewing Technology - TP - Volume - 2-0

P. 225

SEWING TECHNOLOGY - CITS

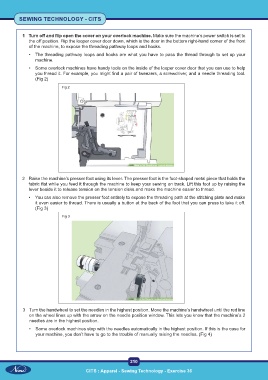

1 Turn off and flip open the cover on your overlock machine. Make sure the machine’s power switch is set to

the off position. Flip the looper cover door down, which is the door in the bottom right-hand corner of the front

of the machine, to expose the threading pathway loops and hooks.

• The threading pathway loops and hooks are what you have to pass the thread through to set up your

machine.

• Some overlock machines have handy tools on the inside of the looper cover door that you can use to help

you thread it. For example, you might find a pair of tweezers, a screwdriver, and a needle threading tool.

(Fig 2)

Fig 2

2 Raise the machine’s presser foot using its lever. The presser foot is the foot-shaped metal piece that holds the

fabric flat while you feed it through the machine to keep your sewing on track. Lift this foot up by raising the

lever beside it to release tension on the tension disks and make the machine easier to thread.

• You can also remove the presser foot entirely to expose the threading path at the stitching plate and make

it even easier to thread. There is usually a button at the back of the foot that you can press to take it off.

(Fig 3)

Fig 3

3 Turn the handwheel to set the needles in the highest position. Move the machine’s handwheel until the red line

on the wheel lines up with the arrow on the needle position window. This lets you know that the machine’s 2

needles are in the highest position.

• Some overlock machines stop with the needles automatically in the highest position. If this is the case for

your machine, you don’t have to go to the trouble of manually raising the needles. (Fig 4)

210

CITS : Apparel - Sewing Technology - Exercise 36