Page 418 - CTS - Sewing Technology - TP - Volume - 2-0

P. 418

SEWING TECHNOLOGY - CITS

5 Wrong stitch density

Causes: The incorrect unwinding of thread form package during sewing. Twisting of needle thread in the

bottom of thread package.

Remedies: The position of the thread guide should be 2.5 times higher than the position of the thread package.

A foam pad should use at the bottom of the thread package. Correct threading of sewing thread during sewing.

6 Uneven stitch

Cause: Incorrect tension of sewing thread. Used incorrect thread path. Incorrect adjustment of needle thread

path.

Remedies: The setting of accurate tension to the thread. Using of accurate thread path. Using of right thread

path.

7 Staggered stitch

Cause: Due to needle deflection, Due to the wrong needlepoint, Incorrect adjustment of needle and thread

size, Due to defected motion of feed dog.

Remedies: Needle size should be increased. The needle should be changed. Needle size and thread size

should be changed. Feed dog motion should be adjusted.

8 Defected stitch

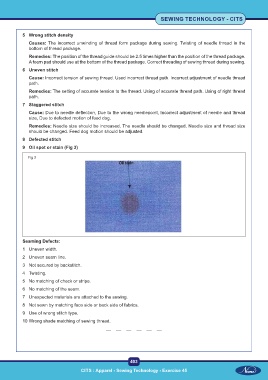

9 Oil spot or stain (Fig 3)

Fig 3

Seaming Defects:

1 Uneven width.

2 Uneven seam line.

3 Not secured by backstitch.

4 Twisting.

5 No matching of check or stripe.

6 No matching of the seam.

7 Unexpected materials are attached to the sewing.

8 Not sewn by matching face side or back side of fabrics.

9 Use of wrong stitch type.

10 Wrong shade matching of sewing thread.

403

CITS : Apparel - Sewing Technology - Exercise 45