Page 224 - CITS - Welder - Trade Practical

P. 224

WELDER - CITS

12 Check for defects like overlap, under cut, porosity and check for correct leg size and throat thickness.

Note: Avoid side-to-side movement of the electrode.

Deslag and clean the root bead thoroughly.

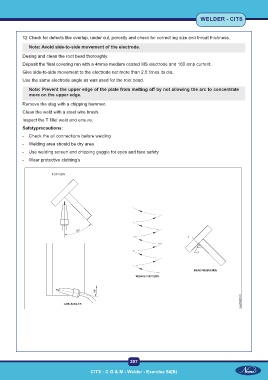

Deposit the final covering run with a 4mmø medium coated MS electrode and 160 amp current.

Give side-to-side movement to the electrode not more than 2.5 times its dia.

Use the same electrode angle as was used for the root bead.

Note: Prevent the upper edge of the plate from melting off by not allowing the arc to concentrate

more on the upper edge.

Remove the slag with a chipping hammer.

Clean the weld with a steel wire brush.

Inspect the T fillet weld and ensure.

Safetyprecautions:

- Check the all connections before welding

- Welding area should be dry area

- Use welding screen and chipping goggle for eyes and face safety

- Wear protective clothing’s

207

CITS : C G & M - Welder - Exercise 54(B) CITS : C G & M - Welder - Exercise 54(B)