Page 28 - CITS - Welder - Trade Practical

P. 28

WELDER - CITS

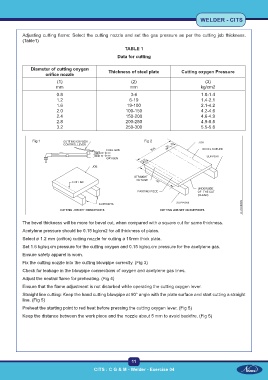

Adjusting cutting flame: Select the cutting nozzle and set the gas pressure as per the cutting job thickness.

(Table1)

TABLE 1

Data for cutting

Diameter of cutting oxygen Thickness of steel plate Cutting oxygen Pressure

orifice nozzle

(1) (2) (3)

mm mm kg/cm2

0.8 3-6 1.0-1.4

1.2 6-19 1.4-2.1

1.6 19-100 2.1-4.2

2.0 100-150 4.2-4.6

2.4 150-200 4.6-4.9

2.8 200-250 4.9-5.5

3.2 250-300 5.5-5.6

Fig 1 Fig 2

The bevel thickness will be more for bevel cut, when compared with a square cut for same thickness.

Acetylene pressure should be 0.15 kg/cm2 for all thickness of plates.

Select ø 1.2 mm (orifice) cutting nozzle for cutting a 10mm thick plate.

Set 1.6 kg/sq.cm pressure for the cutting oxygen and 0.15 kg/sq.cm pressure for the acetylene gas.

Ensure safety apparel is worn.

Fix the cutting nozzle into the cutting blowpipe correctly. (Fig 3)

Check for leakage in the blowpipe connections of oxygen and acetylene gas lines.

Adjust the neutral flame for preheating. (Fig 4)

Ensure that the flame adjustment is not disturbed while operating the cutting oxygen lever.

Straight line cutting: Keep the hand cutting blowpipe at 90° angle with the plate surface and start cutting a straight

line. (Fig 5)

Preheat the starting point to red heat before pressing the cutting oxygen lever. (Fig 5)

Keep the distance between the work piece and the nozzle about 5 mm to avoid backfire. (Fig 5)

11

CITS : C G & M - Welder - Exercise 04