Page 31 - CITS - Welder - Trade Practical

P. 31

WELDER - CITS

Job Sequence

• Wear safety apparel.

• Clean the surface to be cut.

• Set the gas welding plant and fix the cutting blowpipe.

Note: Ensure the cutting nozzle is according to the thickness of the metal.

• Adjust the gas pressure of acetylene and the cutting oxygen.

Note: Ensure the pressure setting as per the metal thickness and size of the cutting nozzle.

• Mark and punch the plate at the required bevel angle.

• Adjust a proper cutting flame.

• Hold the cutting blowpipe at the proper bevel angle to be cut.

• Heat at one end of the plate on the punch line up to cherry red hot.

• Release the cutting oxygen, and observe the cutting action.

• Move the cutting blowpipe towards the other end, following the punched line slowly and steadily at the required

angle.

Note: Maintain a correct speed and distance of the nozzle.

• Close the cutting oxygen and extinguish the flame on the completion of the cut.

• Clean the cut, and inspect for its accuracy.

• Repeat the exercise till you achieve a good and smooth cut.

Skill Sequence

Bevel cutting by hand (Oxy-acetylene)

Objectives: At the end of this exercise, you shall be able to

• set the work piece for bevel cutting

• gas cut bevel surfaces by hand

• inspect the bevel cut.

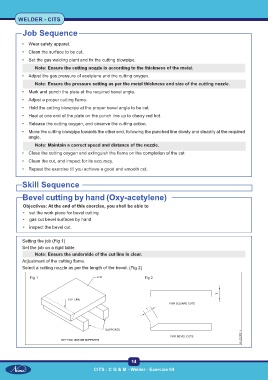

Setting the job (Fig 1)

Set the job on a rigid table.

Note: Ensure the underside of the cut line is clear.

Adjustment of the cutting flame.

Select a cutting nozzle as per the length of the bevel. (Fig 2)

Fig 1 Fig 2

14

CITS : C G & M - Welder - Exercise 04