Page 35 - CITS - Welder - Trade Practical

P. 35

WELDER - CITS

Ensure safety apparel is worn.

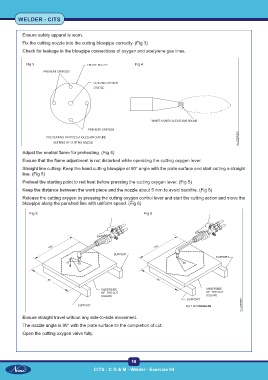

Fix the cutting nozzle into the cutting blowpipe correctly. (Fig 3)

Check for leakage in the blowpipe connections of oxygen and acetylene gas lines.

Fig 3 Fig 4

Adjust the neutral flame for preheating. (Fig 4)

Ensure that the flame adjustment is not disturbed while operating the cutting oxygen lever.

Straight line cutting: Keep the hand cutting blowpipe at 90° angle with the plate surface and start cutting a straight

line. (Fig 5)

Preheat the starting point to red heat before pressing the cutting oxygen lever. (Fig 5)

Keep the distance between the work piece and the nozzle about 5 mm to avoid backfire. (Fig 5)

Release the cutting oxygen by pressing the cutting oxygen control lever and start the cutting action and move the

blowpipe along the punched line with uniform speed. (Fig 6)

Fig 5 Fig 6

Ensure straight travel without any side-to-side movement.

The nozzle angle is 90° with the plate surface till the completion of cut.

Open the cutting oxygen valve fully.

18

CITS : C G & M - Welder - Exercise 04