Page 32 - CITS - Welder - Trade Practical

P. 32

WELDER - CITS

Set the cutting nozzle in the blowpipe and adjust the neutral flame for pre-heating.

Note: Ensure that the flame adjustment is not disturbed while operating the cutting oxygen lever.

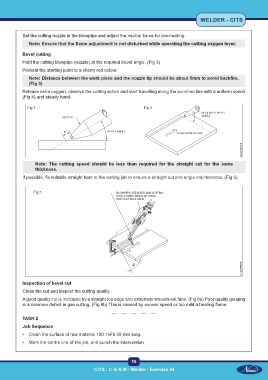

Bevel cutting

Hold the cutting blowpipe (nozzle) at the required bevel angle. (Fig 3)

Preheat the starting point to a cherry red colour.

Note: Distance between the work piece and the nozzle tip should be about 5mm to avoid backfire.

(Fig 3)

Release extra oxygen, observe the cutting action and start travelling along the punched line with a uniform speed

(Fig 4) and steady hand.

Fig 3 Fig 4

Note: The cutting speed should be less than required for the straight cut for the same

thickness.

If possible, fix suitable straight bars to the cutting job to ensure a straight cut and angle maintenance. (Fig 5)

Fig 5

Inspection of bevel cut

Clean the cut and inspect the cutting quality

A good quality cut is indicated by a straight top edge and extremely smooth-cut face. (Fig 6a) Poor quality gouging

is a common defect in gas cutting. (Fig 6b) This is caused by excess speed or too mild a heating flame.

TASK 2

Job Sequence

• Clean the surface of raw material 100 15F6 50 mm long.

• Mark the centre line of the job, and punch the intervention.

15

CITS : C G & M - Welder - Exercise 04