Page 37 - CITS - Welder - Trade Practical

P. 37

WELDER - CITS

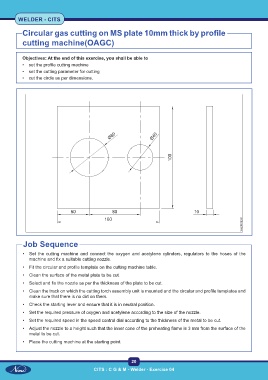

Circular gas cutting on MS plate 10mm thick by profile

cutting machine(OAGC)

Objectives: At the end of this exercise, you shall be able to

• set the profile cutting machine

• set the cutting parameter for cutting

• cut the circle as per dimensions.

Job Sequence

• Set the cutting machine and connect the oxygen and acetylene cylinders, regulators to the hoses of the

machine and fix a suitable cutting nozzle.

• Fit the circular and profile template on the cutting machine table.

• Clean the surface of the metal plate to be cut.

• Select and fix the nozzle as per the thickness of the plate to be cut.

• Clean the track on which the cutting torch assembly unit is mounted and the circular and profile templates and

make sure that there is no dirt on them.

• Check the starting lever and ensure that it is in neutral position.

• Set the required pressure of oxygen and acetylene according to the size of the nozzle.

• Set the required speed in the speed control dial according to the thickness of the metal to be cut.

• Adjust the nozzle to a height such that the inner cone of the preheating flame is 3 mm from the surface of the

metal to be cut.

• Place the cutting machine at the starting point.

20

CITS : C G & M - Welder - Exercise 04