Page 282 - CITS - Welder - Trade Practical

P. 282

WELDER - CITS

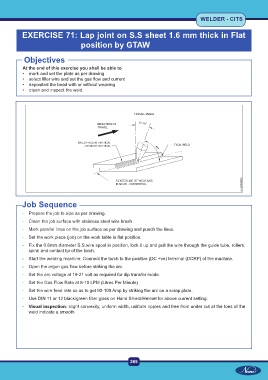

EXERCISE 71: Lap joint on S.S sheet 1.6 mm thick in Flat

position by GTAW

Objectives

At the end of this exercise you shall be able to

• mark and set the plate as per drawing

• select filler wire and set the gas flow and current

• deposited the bead with or without weaving

• Clean and inspect the weld.

Job Sequence

- Prepare the job to size as per drawing.

- Clean the job surface with stainless steel wire brush.

- Mark parallel lines on the job surface as per drawing and punch the lines.

- Set the work piece (job) on the work table in flat position.

- Fix the 0.8mm diameter S.S.wire spool in position, lock it up and pull the wire through the guide tube, rollers,

spiral and contact tip of the torch.

- Start the welding machine. Connect the torch to the positive (DC +ve) terminal (DCRP) of the machine.

- Open the argon gas flow before striking the arc.

- Set the arc voltage at 19-21 volt as required for dip transfer mode.

- Set the Gas Flow Rate at 8-10 LPM (Litres Per Minute)

- Set the wire feed rate so as to get 90-100 Amp by striking the arc on a scrap plate.

- Use DIN 11 or 12 black/green filter glass on Hand Shield/Helmet for above current setting.

- Visual inspection: slight convexity, uniform width, uniform ripples and free from under cut at the toes of the

weld indicate a smooth

265

CITS : C G & M - Welder - Exercise 70