Page 280 - CITS - Welder - Trade Practical

P. 280

WELDER - CITS

Job Sequence

- Clean the base metal surface with the S.S wire brush.

- Clean the base metal surface with alcohol.

- Adjust the current to about 80 to 90A.

- Adjust the gas flow rate to 6-8 LPM.

- Set the root gap to 1.5mm.

- Fix the base metal with the jig.

- Flow the back shielding gas by 4LPM.

- Tack weld at 10mm inside from both ends of the joint.

- Stop the back shielding gas.

- Remove the base metal from the jig.

- Check if the joint has good alignment.

- Fasten the base metal securely to the jig.

- Polish the base metal with the ss wire brush.

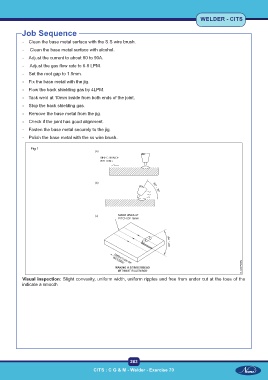

Fig 1

Visual inspection: Slight convexity, uniform width, uniform ripples and free from under cut at the toes of the

indicate a smooth

263

CITS : C G & M - Welder - Exercise 70