Page 276 - CITS - Welder - Trade Practical

P. 276

WELDER - CITS

• Cut the arc and held at the finishing point unit molten metal solidifies.

• Visual Inspection : Slight convexity, uniform width, uniform ripples. And free from under cut at the toes of

the weld indicate a smooth.

Skill Sequence

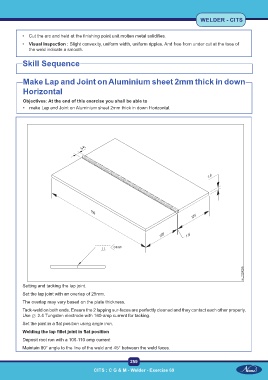

Make Lap and Joint on Aluminium sheet 2mm thick in down

Horizontal

Objectives: At the end of this exercise you shall be able to

• make Lap and Joint on Aluminium sheet 2mm thick in down Horizontal.

Setting and tacking the lap joint.

Set the lap joint with an overlap of 25mm.

The overlap may vary based on the plate thickness.

Tack-weld on both ends. Ensure the 2 lapping sur-faces are perfectly cleaned and they contact each other properly.

Use ∅ 2.4 Tungsten electrode with 160-amp current for tacking.

Set the joint in a flat position using angle iron.

Welding the lap fillet joint in flat position

Deposit root run with a 100-110 amp current

Maintain 80° angle to the line of the weld and 45° between the weld faces.

259

CITS : C G & M - Welder - Exercise 69