Page 275 - CITS - Welder - Trade Practical

P. 275

WELDER - CITS

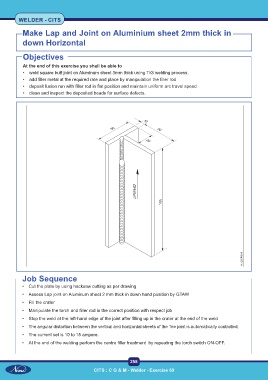

Make Lap and Joint on Aluminium sheet 2mm thick in

down Horizontal

Objectives

At the end of this exercise you shall be able to

• weld square butt joint on Aluminum sheet 3mm thick using TIG welding process.

• add filler metal at the required rate and place by manipulation the filler rod

• deposit fusion run with filler rod in flat position and maintain uniform arc travel speed

• clean and inspect the deposited beads for surface defects.

Job Sequence

• Cut the plate by using hacksaw cutting as per drawing

• Assess Lap joint on Aluminum sheet 2 mm thick in down hand position by GTAW

• Fill the crater

• Manipulate the torch and filler rod in the correct position with respect job

• Stop the weld at the left-hand edge of the joint after filling up in the crater at the end of the weld

• The angular distortion between the vertical and horizontal sheets of the Tee joint is automatically controlled.

• The current set is 10 to 15 ampere.

• At the end of the welding perform the centre filler treatment by repeating the torch switch ON-OFF.

258

CITS : C G & M - Welder - Exercise 69